TRM-IOS is designed to detect industrial oils such as transformer oil (mineral), hydraulic oil, lube oil and heat transfer oil in dry indoor locations. The sensor is positioned on a concrete floor or in shallow drip pan below oil filled equipment and machinery. Reaction time to oils is typically less than 10 seconds after contact.

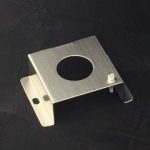

The sensor body has a low center of gravity to sit stably on a flat surface. (An optional stainless hold-down fixture is available.) A replaceable sensor element extends from the bottom surface of the TRM-IOS and the element design incorporates a natural springiness to assure that the element is held in contact with the floor surface. The required activation height is the thickness of the puddle as it spreads across the floor or collects in a drip pan.

TRM-IOS is a passive resistive sensor. When clean and dry, the sensor has a relatively low resistance (< 50 k-ohm). When a puddle of leaking oil reaches the sensor, the resistance climbs to over 1 meg-ohm in a few seconds. Water contact causes a much smaller resistance change. However because the sensor element is a thin layer of material pressed agains the floor, any standing water will prevent the leaking oil from reaching the sensor’s active surface. For this reason, it is important to use the TRM-IOS in locations that are normally dry. A small amount of occasional water will not generate a false alarm and will not cause permanent damage, but the sensor may be rendered inoperative while the water is present. Long term immersion in standing water will dramatically shorten the sensor life

Generally, the type of oils detected by the TRM-IOS will not evaporate. Because the sensor element will not spontaneously evaporate and finding a solvent to rinse away the oil without damaging the sensor material, replacement of the element is recommended. All TRM-IOS sensors are shipped with one element installed and two spare elements. Restoring full service after an oil detection is a matter of seconds, with a quick, tool free element replacement. Additional replacement elements are available for purchase

TRM-IOS may respond to oils and liquids not on the data sheet. Contact the factory for non-listed fluids and testing.

Key Features

Form Factor:

- Compact, low center of gravity for stable positioning on flat surface – Stainless steel hold down fixture available.

Dimensions:

- 3” diameter, 1” thick

Leader cable:

- Supplied with factory standard 2m (6 feet) of two wire leader cable. Wago Lever-Nut quick connects are supplied to daisy chain multiple TRM-IOS devices or to connect to jumper cables. (Maximum recommended jumper cable per daisy chain is 1000 feet)

Sensor Element:

- Replaceable in field without tools.

Integrity Monitoring:

- Missing or damaged sensor element or damaged/disconnected jumper wire generates an alarm condition. This is a “fail safe” design approach because the sensor cannot signal normal conditions while unable to detect a leak.

Response time:

- Transformer Oil (mineral oil), Hydraulic Oil, Lube Oil, Heat Transfer Fluid (DowthermA) – less than 10 seconds at 20 C

- Contact factory regarding fluids not listed on data sheet or for testing.

Reset time:

- Replacement of sensor element is recommended after any leak incident

Simple Apparatus Statement:

- TRM-IOS qualifies as “Simple Apparatus” per CSA /EN/IEC/UL 60079-11 Clauses 5.7 a and b. As such TRM-IOS may be installed in hazardous areas when connected to the monitoring device via an approved zener safety barrier. No barrier is required for ordinary are installations. TRM Sensors recommends the MTL 7760ac zener barrier.

Recommended monitoring options:

- Up to 3 TRM-IOS sensors may be monitored by TRM-Easy5-Relay-U