TRM-HX is designed to detect leaking acids, bases and similar highly conductive corrosive fluids. TRM-HX probes ignore rain water, snow melt, and condensation. TRM Probes typically do not respond to any hydrocarbon liquid (gasoline, diesel, Jet fuel, crude oil or natural gas condensates), however they do respond to oil field brine in many cases.

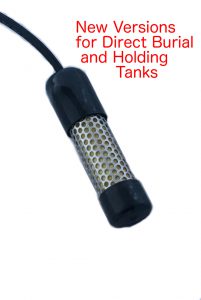

TRM-HX is available in two versions. Version 1 is a vertical probe designed for installation in sumps, pipe trenches and other outdoor containments. The 2” diameter outer stainless steel screen protection from mechanical impact. Version 2 is designed to be used for double wall tanks. It can be installed through the outer wall of an above ground containment tank or dropped into the interstitial space between inner and outer wall. Version 2 can be supplied in wither SS316 stainless steel or Grade 2 titanium depending on the nature of the corrosive chemicals to be monitored.

TRM-HX Version 1 is supplied with 10 meters (32 feet) of outdoor, tray rated two wire leader cable. Version 2 is supplied with 3 m (10 feet) of leader cable. Special lengths are available on request.

TRM-HX is resettable and usually resets as soon as the probe is removed from the detected fluid. Probes that have been contaminated with dirt or mud can be rinsed in tap water.

TRM-HX should be monitored by TRM-Easy5-Relay-U or TRM-Easy5-Panel. An important aspect of the TRM-Easy5-Relay or Panel is the ability to control the alarm threshold via the use of external reference resistors. Acids, bases, other corrosive solutions and many inorganic slat solutions are highly conductive compared to rain water, snow melt or condensation. The variable threshold capability of the monitoring devices in conjunction with the TRM-HX probe allows the installer to “tune-out” the local sources of casual water (including ground water and surface run-off in many cases) while still maintaining the sensitivity to respond to the targeted corrosive fluid.

CSA Group has examined TRM-UST and considers the sensor to be “Simple Apparatus” per CSA /EN/IEC/UL 60079-11 Clauses 5.7 a and b. As such TRM-UST may be installed in hazardous areas when connected to the monitoring device via an approved zener safety barrier. The safety approvals granted to the zener safety barrier apply to the installation as a whole.

Key Features

Dimensions:

- Version 1: Through the wall sensor for double wall chemical tanks

- Version 2: Direct bury brine sensor: 1” diameter x 4” total length brine injection piping

- Version 3: 9″ vertical sensor for sumps and containment trenches

Leader cable:

- All version supplied with 5m of two conductor leader cable

Response time:

- Acids, Bases other conductive corrosives < 3 seconds

- TRM-HX ignores rain water, snow melt and condensation

- TRM-HX ignores refined fuels and most crude oils, but may respond to oil field brine

Reset time:

- Immediately on removal from detected liquid

Simple Apparatus Statement:

- CSA Group has examined TRM-HX and considers the sensor to be “Simple Apparatus” per CSA /EN/IEC/UL 60079-11 Clauses 5.7 a and b. As such TRM-HX may be installed in hazardous areas when connected to the monitoring device via an approved zener safety barrier. The safety approvals granted to the zener barrier apply to the installation as a whole. TRM Sensors recommends the MTL 7760ac zener barrier. One barrier and one TRM Relay Unit Type-CV is required for each TRM-HX probe

Recommended monitoring options:

- TRM-Easy5-Relay (UL/CSA Approved DIN Rail Module or TRM-Easy5-Panel (UL508A Certified)