We respond to unique needs with custom modifications and rapid prototyping of new products.

CASE STUDIES OF PAST CUSTOM SOLUTIONS:

A combination fuel and brine detector that emulates a PT1000 RTD sensor. Designed for compatibility with existing wireless mesh network.

North Sea oil and gas production platforms have miles of insulated pipe. Most of the pipe is exposed to wind-blown sea water and occasional salt water deluge from the testing of the fire suppression systems. Sea water intrusion and resulting corrosion is a major maintenance concern that requires frequent inspections. In the worst case scenario corrosion leads to a crude oil or gas (and gas condensates) leak.

CLIENT’S INDUSTRY: Off-Shore Oil Production

PROBLEM: The client asked for a leak detector that would react to the presence of salt water or leaking hydrocarbon liquids trapped beneath the insulation cladding. But since retro-fit wiring cost on off-shore platforms is extremely expensive so a wireless solution was desired. Economical, wireless mesh systems are available from major instrumentation suppliers, but these systems are not designed for leak detection probes.

SOLUTION: Make the leak detection look like a temperature sensor.

A trimmed resistor network encapsulated in the top of the probe, makes the sensor appear to the mesh system as if it were an RTD temperature sensor. With no leaks, the reported “temperature” is near 0˚C. A salt water detection appears to make the temperature drop to -10˚C or lower while a hydrocarbon leak makes the sensor report a “temperature” above 60˚C. Using the pre-existing telemetry software with its programmable upper and lower temperature limits, the already installed monitoring equipment, is able to monitor hundreds of new leak detection sensor probes.

Used oil sensor, developed for double wall holding tanks at retail oil change facilities.

Used Oil Sensor

Every wonder what happens to the used oil drained from your car when you visit a drive through oil-changer facility? Answer: It’s held in an underground storage tank until a tanker truck arrives to pump it out and take it to a recycling facility. But the used oil is very toxic and many states required that the holding tank must be double wall. Any oil leaking from the inner tank will be collected, at least temporarily, by the outer shell. A probe installed in the interstitial space between inner and outer tank is in the ideal location to detect failure of the inner tank.

CLIENT’S INDUSTRY: Retail Oil Change Facilities

PROBLEM: Oil holding tanks are much smaller than traditional underground fuel storage tanks and the space between inner and outer wall is too small for commercially available sensors for fuel tanks.

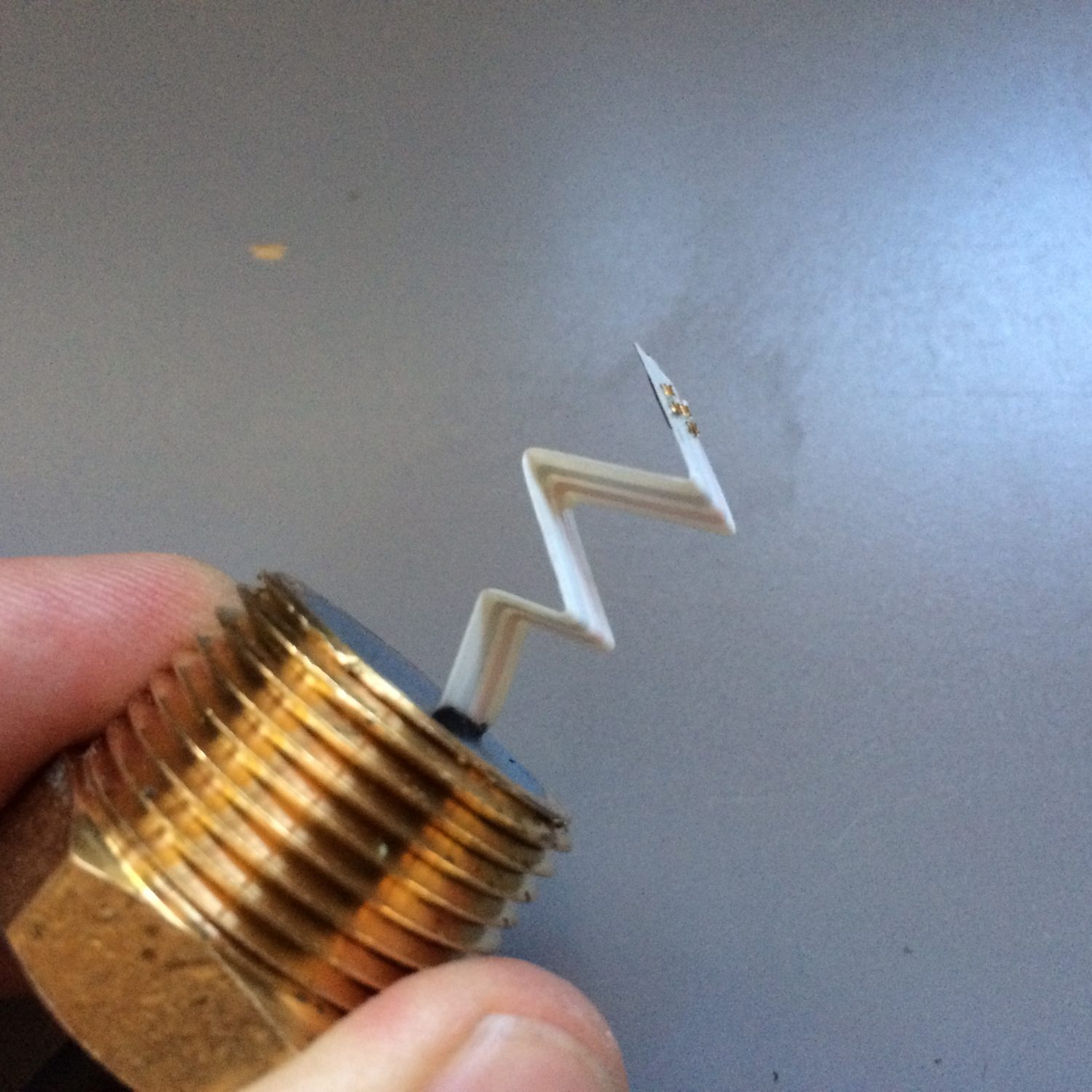

SOLUTION: A probe that can be installed through the outer tank wall, with a flexible and collapsible sensor element that adjusts to the available space.

The sensor technology was off-the-shelf, but the mechanical adaptation was a special requirement requiring a unique solution.

Small diameter, tri-axial, combination crude oil and sea water sensor developed for insulated pipe on off-shore rigs.

Low Mass Oil/Sea Water Detector

CLIENT’S INDUSTRY: Petro-Chemical

PROBLEM: The client needed to monitor beneath the cladding of insulated pipe in order to detect sea water or gas condensates. However, the pipe system was subject to high levels of vibrations and the probes needed to be mounted through the relatively low strength cladding. In order to survive the mechanical stress, the probe needed to be small and with as little mass as possible.

SOLUTION: A tri-axial, combination fuel/brine probe using mineral insulated cable as a framework.

This is a very unique probe that combines a conductivity measuring circuit and a concentric hydrocarbon detecting circuit that share a common electrode. By using commercially available copper based Mineral Insulated heating cable with an outer copper shell, a very small and light probe was fabricated. The threaded plastic cable gland was selected to provide a water tight seal around the probe. The entire assembly weighed in at less than 50 gm.

Optical level detector with special adapter circuit to create a fast acting “any fluid” detector.

Optical “Any Fluid” Detector

Legacy systems (e.g. TraceTek) offer some strong advantages with cable based leak detection systems. However, one noted weakness for cable systems is their relatively slow response to leaking solvents.

CLIENT’S INDUSTRY: Pharmaceuticals

PROBLEM: Client needed to supplement their existing cable leak detection system with fast acting optical probes but the output of the probes needed to be compatible with the installed cable type system.

SOLUTION: A special adapter circuit that converted the output of the optical probe to a signal that could be monitored by the cable type leak detection instruments.

This solution did not require development of a new sensor, but the project is a good example of TRM Sensors’ capability to offer a quick response and cost effective solution to a very specific niche market.

“Water-in-Fuel Tank” probe to detect water accumulating in the bottom of fuel oil tanks.

Water-in-Fuel Tank Sensor

Bulk fuel is frequently delivered with a small fraction of water. When the fuel is stored in an underground tank, the water eventually settles and accumulates at the bottom of the tank where it can cause corrosion. Special water indicating paste can be stuck to the end of a dip stick, but manual inspections may not be reliable.

CLIENT’S INDUSTRY: Wholesale Fuel Distributor

PROBLEM: The client wanted a method to automate water detection at the bottom of tanks containing heavier fuel oils. Manual “sticking” had proven to be unreliable and an out-of-service inspection revealed the onset of corrosion that might have eventually caused a leak had it not been discovered.

SOLUTION: A stainless steel probe and a plastic mesh spacer tube was designed to meet the clients requirements. The probe had to fit through a small diameter access port, be heavy enough to maintain a vertical alignment and not be too heavy for the supporting cable. The plastic mesh spacer prevented the twin electrodes from accidentally shorting on the steel floor plates. The length of the plastic mesh spacer provided a degree of control over the depth of water required to trigger the sensor. Testing with heavy fuel oil verified that the stainless steel electrodes would not be permanently fouled by the heavy oil. TRM Relay Unit Type-CV proved to be an effective monitoring device.

“Flexible Fuel-in-Coolant” sensor to detect traces of diesel or gasoline in engine coolant.

Fuel-in-Coolant Sensor

Internal combustion engines are cooled using water/glycol coolant circulated through the engine block and head to a radiator. Most engine coolant systems include a coolant expansion tanks which accumulates expanding coolant as the engine heats up, then returns the coolant to the main system when the engine cools. In essence, the expansion tank takes a fresh sample of coolant for every engine start/stop cycle. Any traces of fuel in the coolant are an early indicator of gasket wear, head distortion or a cracked engine block.

CLIENT’S INDUSTRY: Automotive/Trucking

PROBLEM: The client wanted a method to detect traces of fuel in the engine coolant, since the presence of fuel could be an early indicator of serious engine problems. An easy to integrate electrical sensor is desired so that it can be incorporated in the On Board Diagnostics common in all modern internal combustion engine systems.

SOLUTION: A simple passive resistor based system fabricated with silicone insulated wire and carbon/silicone conductive materials. The flexible nature of this sensor allows the sensor to be installed via the filler neck of the coolant expansion tank. Assembled length of sensor portion and lead wires is easy to adjust to accommodate different coolant tanks and engine compartment layouts.