Monitoring for water leaks in the vicinity of steam pipe and pressurized condensate return lines requires any products to survive in a high ambient temperature. The entire TRM WaterWire®-HT system is designed to operate continuously in temperatures up to 232°C (450°F). The system can detect and accurately locate a puddle of water that is likely to form nearby the actual steam leak. Live steam itself in vapor form is not detected.

Steam Conduit Monitoring

TRM Sensors developed TRM WaterWire®-HT and all of the associated system components with one thing in mind: survive in very high ambient temperature for a number of years and still be able to detect and locate a puddle of water should the steam or condensate leak occur. The sensor cable is small enough (about 4 mm x 2.5 mm) and flexible enough to be pulled through a number of direction changes within the containment pipe. When liquid water is absorbed into the porous cable sheath, the monitoring system detects the water and calculates the location along the cable run.

In addition to the sensor cable itself, the complete system includes feed through fittings, branch connectors, jumper cable, splice kits and a special installation tool. Check TRM WaterWire®–HT under the Products tab or click on the links below for details on the complete line-up of “HT” components.

System Components

TRM WaterWire®-HT Sensor Cable

TRM WaterWire®-JC Jumper Cable

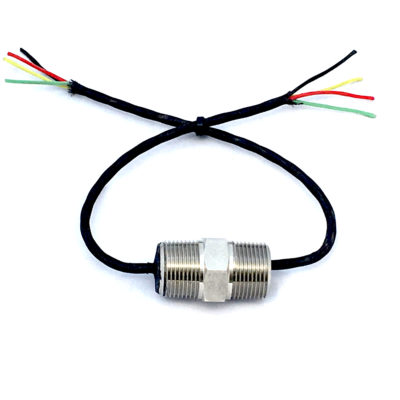

TRM WaterWire®-FTF Feed Through Fitting

TRM WaterWire®-BC Branch Connector

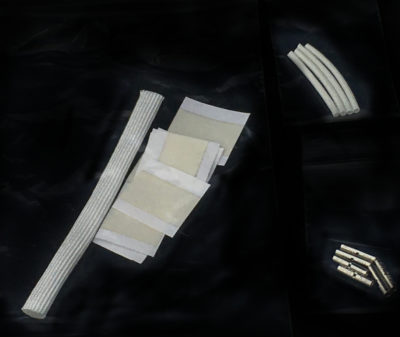

TRM WaterWire®-USK Universal Splice Kit

TRM WaterWire®-CT Crimp Tool